Process Piping Engineering and Design Services

Regulatory Compliant Process Piping Designs

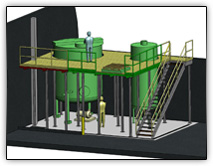

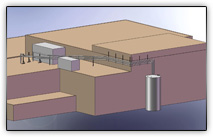

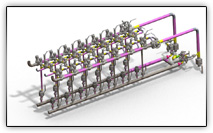

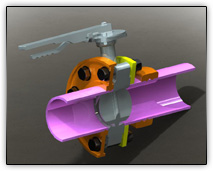

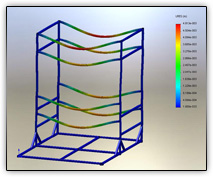

As a design build company, Pipers Mechanical can both design and install your process piping project. Our highly skilled engineering and design department has the experience and technical expertise to help you develop your project from the ground up. Our design team will design your project to your specifications, while suggesting options that can save you money and time. Our in-house 3D solid modeling capabiltities offer significant benefits in terms of communications, planning and project execution over conventional 2D plans and drawings. Our designs always comply with applicable regulations and codes.

From P&I Diagrams to Real World 3D Solid Modeling

Our clients typically supply basic P&ID documents in addition to general configuration drawings. Our scope of work ranges from a simple "walk-through," in which we develop the route layout design, to extremely detailed custom builds with exacting specifications. We have the capability to develop detailed information based on the documents and efforts undertaken during the project.

We can supply drawings at any level of detail, from the overall facility to individual components. At the conclusion of your project, Pipers Mechanical can furnish all documentation in "as built" condition. The types of documents and drawings that Pipers Mechanical can prepare include:

- Block diagrams

- Process & instrumentation diagrams

- Mass flow diagrams

- Process flow diagrams

- Process data sheets

- Circuit diagrams

- Mechanical flow diagrams

- Equipment location diagrams

- Installation drawings

- Digital renderings

- Digital pictures

Our Four-Step Process

Pipers Mechanical generally follows a four-step process during the design phase of a project. Using computer models, Pipers Mechanical can develop visual representations of a project on any scale and at any level of detail. Our goal throughout this interactive process is to develop designs that exactly match our clients' needs, expectations and vision.

Development

This phase includes scale-up from laboratory and pilot plant; risk assessments, including FMEA and HACCP; characterization and determination of critical process parameters; and plant and process feasibility studies.

Design

This phase includes establishing the conceptual basis of the design; establishing the process flow diagrams and design criteria; and determining critical process parameters.

Optimization

This phase includes optimizing the design for personnel, material and information flow; reducing waste, variation and cycle times; increasing yield, throughput, reliability and profitability; process tracking, trending and model predictive control. This phase takes a comprehensive approach to optimize process performance and plant utilization.

Execution

This final phase of the design process includes site master planning; facility and process utilization and optimization; site surveys; and financial analysis and justification.