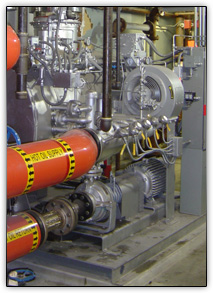

Hot Oil Heating

Project Overview

Many chemical plants rely on steam for adding heat externally or through coils to their process, which does not provide a consistent heat transfer medium for controlling process heating applications. One of our clients wanted to investigate using a hot oil heating system for their chemical processes, which provides more consistent heating and can maintain higher temperatures than a steam heating system.

Pipers Mechanical worked with a vendor to select the components for the new heating system, then designed the piping and the controls. We also guided the client through the regulatory requirements governing this type of heating system.

Why Pipers Mechanical

Pipers Mechanical was the perfect choice for this project because of the our:

-

Knowledge and Experience

Pipers Mechanical was chosen to spearhead this project because of our extensive experience with various types of heating sytems. The engineering staff selected components for driving the system that fit the client's requirements, including the valves and the controls. Pipers Mechanical designed the layout for the entire system, including the looping and the vessels that were going to be fed, and sized the system for future expansion.

-

Knowledge of Compliance Issues

Because of the high temperatures and high pressure welds involved, hot oil heating falls under a different set of regulations than low pressure steam heating does. This client had no previous experience with hot oil heating and depended on Pipers Mechanical to guide them through the new code requirements. Pipers Mechanical:

- Secured material data sheets for all the piping and fittings

- Ensured that the piping met the power piping specifications under ASME B31 standards

- Compiled a full documentation package for the client

- Ensured that the system was reviewed and inspected by the State of Wisconsin