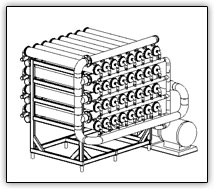

Membrane Micro-Filtration Skids

Project Overview

Pipers Mechanical was asked to design and build three different types of high-quality, high purity membrane micro-filtration skids in a bio-enzyme plant. The project required a total of five skids using stainless steel tubing and pipe that varied from 1/2 inch to 14 inches in diameter. Working from a flow diagram, a rough design and general specifications for materials and methods, Pipers Mechanical:

- determined the constructibility of the project

- established a budget

- designed the skids

- fabricated the skids

- installed the skids in the client's plant

Why Pipers Mechanical

Pipers Mechanical was the perfect choice for this project because of our:

-

Experience working with stainless steel and welding capabilities

Pipers Mechanical's engineers and fabricators have the training, skills and experience to work with the materials required for this project and to produce the high quality welds required.

-

In-depth knowledge of materials and methods

Pipers Mechanical's in-depth knowledge of materials and methods meant that our engineers could work from initial diagrams to design skids that met the client's requirements for quality, purity, functionality and size. Pipers Mechanical took the time to fully understand the project and all of the details — from large-scale design issues down to the equipment connection style, venting and drainage. Our engineers made sure that all of the parts, whether fabricated by Pipers Mechanical or secured from outside suppliers, fit and worked together seamlessly.

Pipers Mechanical was also able to save the client money by suggesting materials that met the specifications for the process, but cost less than materials originally specified for the project.

-

3D solid modeling capabilities

Pipers Mechanical produced 3D solid models of the skids, which were used in communications between our staff and the client's staff. 3D solid models were especially effective in the project because:

- client staff working in other countries could readily understand the design in spite of language barriers

- the models allowed Pipers Mechanical to ensure that the skids would fit in the space allotted to them in the plant

- the client's operations staff could give input during the design phase, when changes could be incorporated into the design to ensure that components were adequately accessible for maintenance

-

Adherence to sanitary process design and construction methods

Typical of projects in food, chemical and pharmaceutical industries, this project required scrupulous attention to purity and compliance with safety and sanitation regulations. Pipers Mechanical's long experience with and knowledge of the regulatory and safety requirements for the projects like this one ensured that the skids would meet the compliance benchmarks.

-

In-house fabrication shop

Pipers Mechanical's ability to fabricate the entire project in its in-house fabrication shop minimized disturbance at the client's site.